For more than seven decades, K+K Klaas + Kock has been impressing customers with high-quality food and products from the region. But the topic of digitalization also drives the retail company. The latest milestone in the consistently pursued IT strategy is the implementation of a warehouse management system. With its help, processes in the area of intralogistics will be aligned more efficiently and made even more flexible in order to be well equipped to respond to current and future challenges in a demanding market segment.

K+K Klaas + Kock B.V. & Co. began in 1950 with the confectionery business. With a keen sense for the potential expansion rates associated with the emerging wave of discount stores, the merchants established a large-space store in Nordhorn for the first time just six years later.

Regional strength as a recipe for success

A good 7,000 employees at K+K ensure that customers can rely on the promise of quality and freshness. The range of standard products is constantly supplemented with trendy and seasonal products. In addition, meat and sausage specialties under the “drilander” brand are produced in the in-house butcher’s shop. K+K has also made a name for itself as one of the largest reusable drinks suppliers in North Rhine-Westphalia. The selection currently comprises around 18,000 different items, which are delivered to the sales outlets via the fleet of around 120 vehicles.

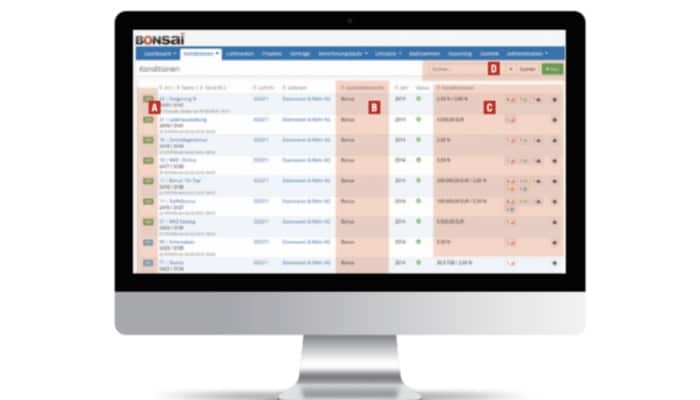

Regional strength is a building block of the success concept, albeit an elementary one. At the same time, K+K is using the potential of digitalization to keep pace with its ongoing expansion and to make the company more flexible and efficient. In 2011, GWS Gesellschaft für Warenwirtschafts-Systeme, Münster, installed gevis ERP, an ERP solution that helped to achieve numerous objectives: optimized master data management, electronic invoice verification and management as well as the handling of ordering processes via EDI and the Internet. There is also a web store through which supermarkets within a radius of 150 km can order goods on offer directly.

Consistent continuation of the digitalization strategy

In 2016, the go-ahead was given for the further development of the IT infrastructures. “In order to do justice to the sensitivity of our consumers, we have always attached great importance to the highest food quality combined with sustainability and transparency,” says Rob. Verbunt, the project manager responsible for the WMS digitization project at K+K. “In order to be able to guarantee this in the long term and at the same time act in an economically secure manner, the logistical processes had to be designed and reorganized to be functionally reliable. K+K therefore decided to introduce a warehouse management system”.

The winner was pL-Store Foodline from proLogistik, a software solution for warehouse management. Their proverbial specialty is that all central applications for food retail are already stored there as standard. Highlights include online inventory management, parallel picking options, expiry date processing with monitoring of remaining shelf life, space management including optimization processes and customer-specific labelling of goods.

“The decision in favor of proLogistik was also supported by the fact that the intralogistics system house was able to supply the necessary hardware from a single source at the same time and we didn’t have to look for another provider,” Mr. Verbunt adds. In addition, the warehouse management system from proLogistik already has a standardized interface to the gevis ERP | NAV from GWS Gesellschaft für Warenwirtschafts-Systeme, so that any connection problems could be ruled out from the outset.

Phase model minimizes commissioning risks

The first specification meetings took place in July 2016. The pL-Store Foodline-LVS was put into operation for the first time in March of the following year. The phase model agreed between K+K and proLogistik provided for a total of ten start-ups:

The great advantage of this approach is that the underlying complexity of the project can be reduced and risks minimized. Affected employees also benefit from “training on the job” and can gradually familiarize themselves with the new work processes.

Sectoral LVS supplemented by individual applications

In addition to the standard functions in pL-Store Foodline, proLogistik has also implemented an additional function for multiple transports. This is important for K+K because individual vehicles in the in-house forklift fleet physically and systemically pick up several pallets at the same time and set them down at transfer points. There, the load carriers are picked up by other industrial trucks and individually distributed to assigned storage locations. In addition, various exchange article processes to be automated had to be taken into account. Put simply, as soon as article A is discontinued and becomes article B, the WMS automatically supports this transition without the need to synchronize stocks or documents.

There are also permanent exchange items. If item A and item B are practically equivalent for customers, the system can automatically consider the stocks of both goods for delivery. There is also the “Auto cancel” function. Because manual cancellation is not an option due to the volume of documents and the business relationships between the store as customer and the central warehouse as supplier, undeliverable quantities are automatically canceled under certain conditions in order to optimize processes.

Robust hardware for paperless order processing

Instead of walking or driving along the rows of shelves in the central warehouse with order lists, employees now use mobile hardware “made in Germany”, which has replaced the error-prone and time-consuming paper-based system. Devices of the pro-V-pad type from proLogistik are used. These have an impact-resistant plastic housing and an extremely stable, hardened and wear-free capacitive touch surface.

Quality promise secured for the future

With the introduction of a new ERP solution and the subsequent introduction of the warehouse management system pL-Store Foodline from proLogistik, the long-established retail company K+K Klaas + Kock B.V. & Co. KG, which is celebrating its 75th anniversary this year, has taken decisive steps into the digital age. Nevertheless, people continue to play a decisive role. “Our warehouse staff now also appreciate the system support, it makes things easier and quicker for them and there are fewer errors,” sums up K+K project manager Mr. Verbunt. “Last but not least, the transparency gained over all stocks in conjunction with reduced handling effort and improved security of supply are important,” says Rob. Verbunt continues. After all, K+K wants to remain close to its customers, who place their trust in the retail company.