pLG WMS

Our Warehouse Management System of the pL Group

Successfully in use with well over a thousand installations- Order-oriented picking

- Multi-stage picking

- Multiorder picking

- Parallel picking

- Freestyle picking

- Picking ready for dispatch

- Store-specific order picking

- Goods-to-person picking

- Pick-to-Light

- Put-to-Light

- MHD-controlled picking

- Work & packing stations

- Labeling

- Logistic manufacturing

- Assembly, packaging & display construction

- Quality control

- Order picking

- Returns management

As the market leader for ERP-independent warehouse management systems, we know the challenges our customers face.

pLG Warehouse Management System

OVERCOMING CHALLENGESVolatile markets, ongoing cost pressure, fluctuating demand, increasingly small orders and the demand for ever shorter delivery times combined with maximum delivery quality and returns management.

We support both small and large companies that are replacing systems or introducing a Warehouse Management System for the first time with tailor-made software solutions for their digital transformation.

What our customers say

The great advantage of proLogistik is that the company can offer both the warehouse management software and the necessary hardware from a single source.”

IT-Leiter, Ostendorf Kunststoffe

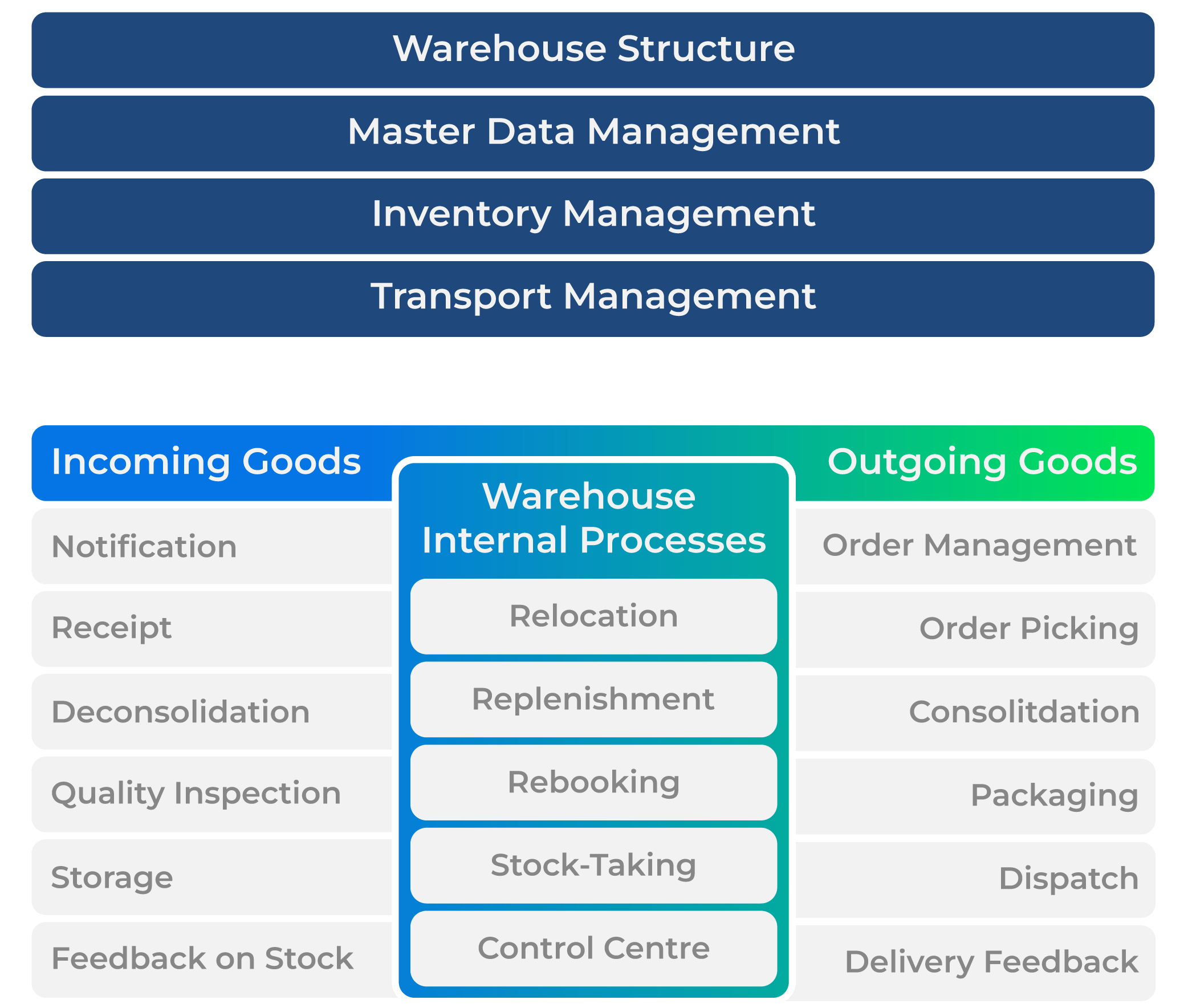

The core functions of our Warehouse Management System

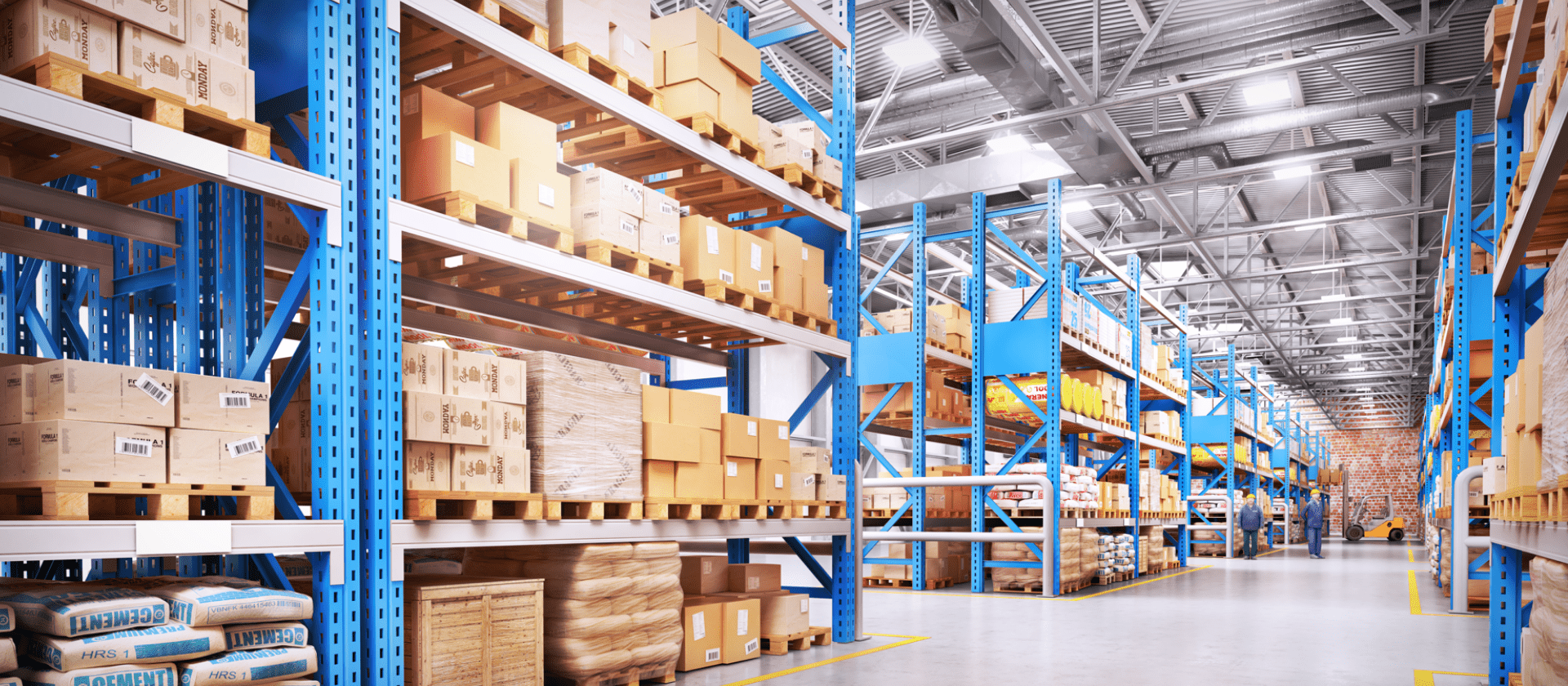

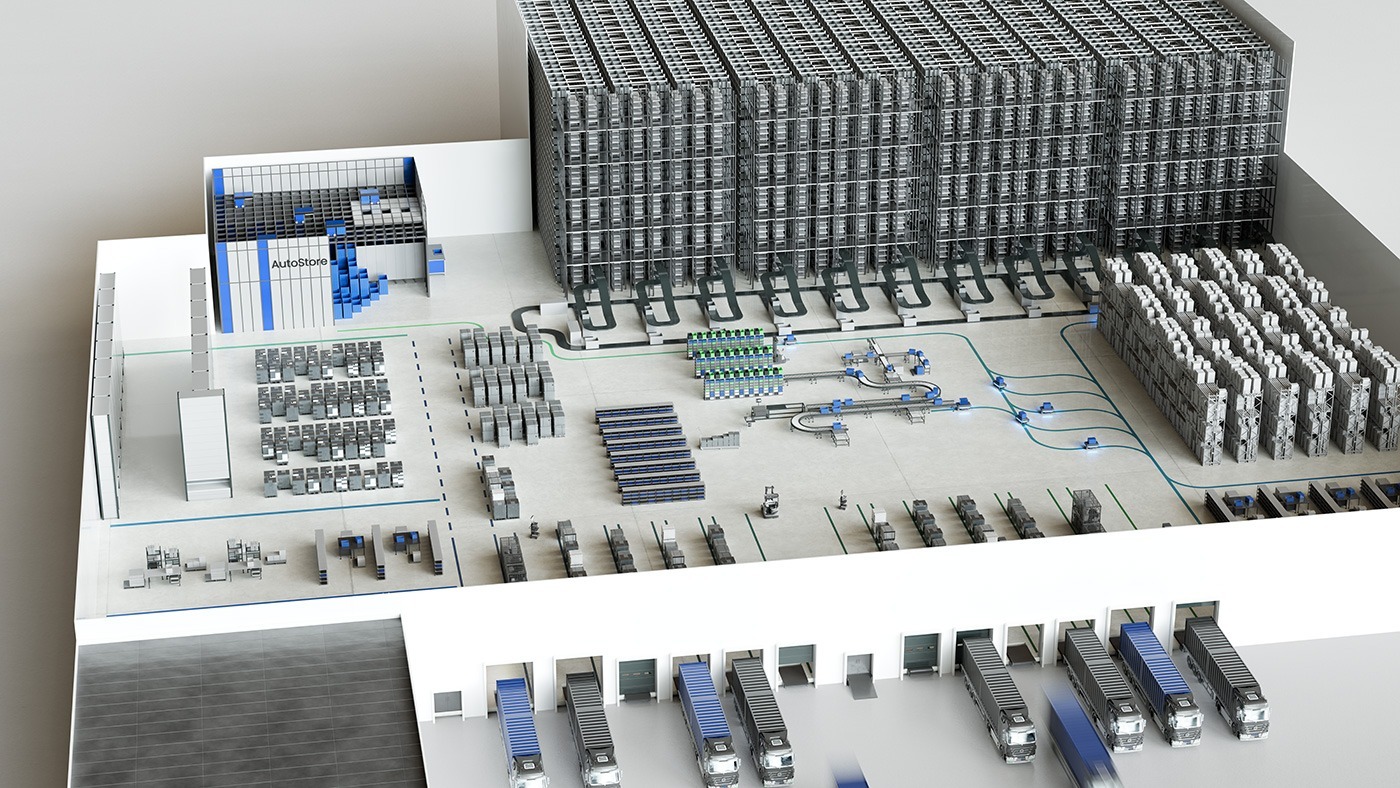

THE PRODUCT SOLUTION FOR EFFICIENT WAREHOUSE MANAGEMENTThe warehouse processes are precisely coordinated and, in addition to efficient control of material flows and stock management, also enable orders to be processed and safe workflows to be guaranteed.

Seamless integration into existing systems

Our pLG Warehouse Management System can be easily connected to all standard ERP systems via interfaces. The standard interfaces of the respective ERP/PPS provider, such as SAP, Infor, Microsoft Dynamics or ProAlpha, are preferably supported. Further interfaces are made available by us on an ongoing basis.

pLG WMS – additional functions

Always up to dateAt the proLogistik Group, we aim to continuously develop our WMS in order to integrate the latest technological innovations and respond precisely to the individual requirements of our customers.

- Empties and loading aids

- (Multi-)client capability

- Multiple storage capability

- Forklift guidance system

- Value Added Services

- Billing module

- Consignment

- Batches & minimum shelf life

- Autostore & lift cabinet module

- Double/multiple depth storage

- Dangerous goods/Hazardous materials

- Weight control

- Cross Docking

- Package optimization

- Production supply

- Resource planning

- Returns management

- Serial numbers

pLG WMS – ideal for these industries

Custom-fit, individual & solution-oriented

WHOLESALE

RETAIL

INDUSTRY

3-PL

E-COMMERCE

Top quality that pays off

WHAT OUR CUSTOMERS SAY“Even growing and changing requirements can be flexibly implemented at any time thanks to the proLogistik Warehouse Management System whose range of functions fully covers 3PL specifics.”

“Typical examples include an extremely wide range of items, varying handling processes and variously designed storage locations. This saves time, as there is no need to program a large number of functions. In addition, the

warehouse management software is the expression of proven process knowledge on the part of the manufacturer.”

Discover the many advantages of the pLG WMS

Advantages in figuresWith our solution, you can reduce costs, minimize effort and gain more time for the essentials.

The perfect addition to your warehouse management system

pLG Business IntelligenceTogether with the pLG BI tool, you can make data-based smart decisions.

An english version of our proLogistik Group image brochure.

We will be happy to advise you on our products

We are here for you.Give us a call or send us a message. We look forward to welcoming you.

proLogistik Holding GmbH

Fallgatter 1

44369 Dortmund

Tel.: +49 (0) 231 5194-0

Tel.: +41 (0) 44 200 40-00

Tél.: +33 (0) 251 81 85 85

proLogistik Holding GmbH

Fallgatter 1

44369 Dortmund

Tel.: +49 (0) 231 5194-0

Tel.: +41 (0) 44 200 40-00

Tél.: +33 (0) 251 81 85 85