Intralogistics – Virtual warehouse tour with 360° warehouse tour

Intralogistics – Virtual warehouse tour

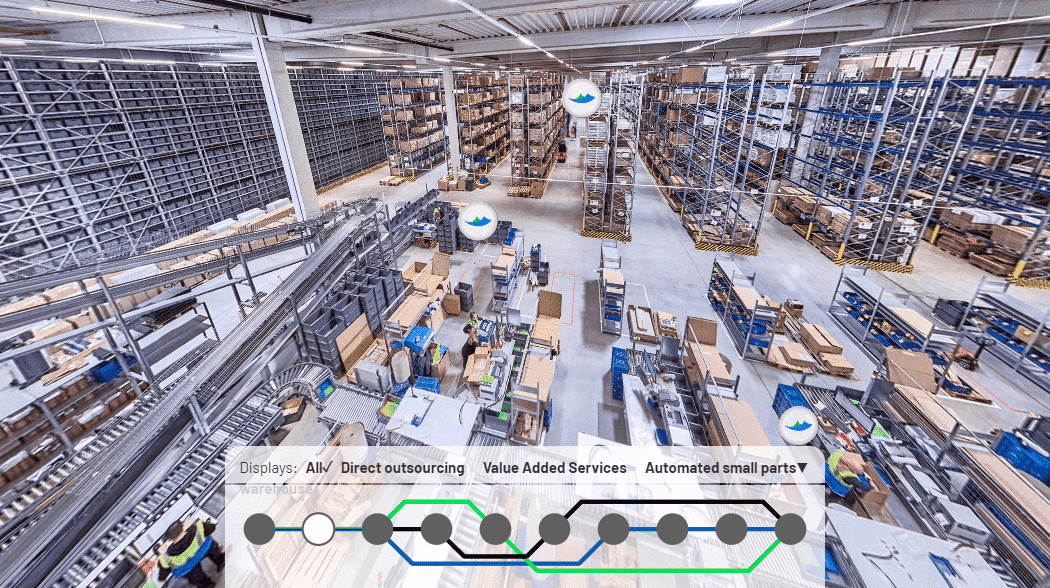

a real 360-degree experienceWould you like to find out in advance about the many possibilities of the pLG WMS warehouse management system? No problem – with our intralogistics 360-degree warehouse tour, you can move through our warehouse at your leisure and gain a detailed impression of our pLG WMS.

One of the highlights of our advanced solutions is the option of virtual warehouse tours. The innovative technology enables interested parties and customers to see our intralogistics systems in action without having to leave their office.

By the way: If you wish, you can of course also obtain detailed information without the Intralogistics 360° virtual warehouse tour. We have briefly summarized the most important information for you. And if you still have any questions, just get in touch with us. We would be pleased to help you further.

Intralogistics – what sets our approach apart

Our experience in intralogistics is characterized by constant innovation and the deep conviction that every challenge has a solution. Here are some of the pillars of our strategy that position us as a pioneer in the industry:

- Customer-centric solutions: We develop systems that are tailored to the individual needs of each warehouse to ensure maximum efficiency and productivity.

- Innovative technology: We rely on innovative technologies, such as the KNAPP shuttle system and specially developed software systems. In this way, we ensure that your intralogistics is equipped for the future and meets the increasing requirements.

- Data-driven optimization: We use data analytics to make informed decisions and drive continuous improvement in all aspects of intralogistics.

- Comprehensive integration: Our systems are designed to integrate seamlessly into existing processes, ensuring end-to-end efficiency and consistency.

- Automation for efficiency: We rely on automation to reduce manual errors, increase safety and reduce operating costs.

- Sustainable practices: Our solutions promote sustainability by supporting resource efficiency and environmentally friendly practices.

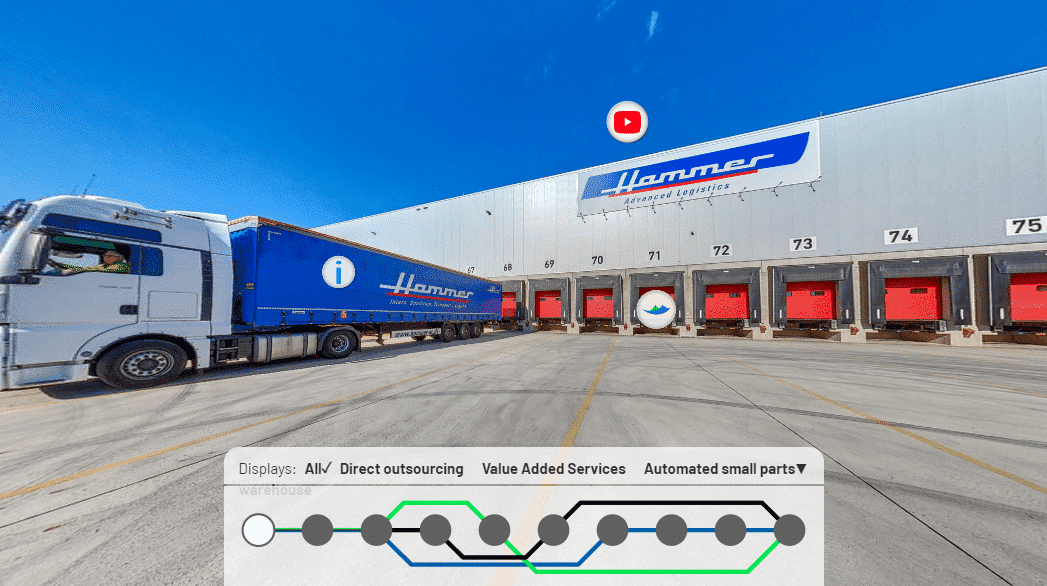

Exterior view of intralogistics warehouse – facts & figures

proLogistik Group

Since 1983, proLogistik has been implementing innovative software and hardware solutions, including those for intralogistics. Today, more than 800 employees work in development, production and service.

Hammer Group

The Hammer Group is a symbiosis of logistics companies and related industries with its headquarters in Aachen. The Group has access to 350 vehicles, employs 700 people and generates an annual turnover of €135 million.

The range of services is all-encompassing and extends from customized national and European overland transportations based on our own state-of-the-art vehicle fleet to air and sea transportations with our own bonded warehouse, fully monitored security transports, special silo and bulk goods transportations, heavy and plant transportations and special Eastern European transportations.

LCE – Logistics Campus Eschweiler

The Eschweiler logistics campus of Hammer GmbH & Co. KG is centrally located on an area of over 105,000 square meters with direct access to the A4 motorway.

- Property: 186,000 square meters

- Usable floor space: 104,000 sqm

- Floor area: 93,489 sqm

- Mezzanine floor: 9,876 sqm

- Offices and social areas: 1,789 sqm

- Employees (planned): 350

proLogistik controls intralogistics with the warehouse management system pLG WMS at the logistics center on the Eschweiler campus. Since then, Hammer has been able to implement any customer requirements on an ongoing basis with complete flexibility.

Essential elements of intralogistics: optimization of processes and technology

The integration of advanced systems and technologies is not only a feature of advanced facilities, but also a key factor for companies wishing to remain competitive in an increasingly competitive market. At proLogistik, we cover the many aspects that are essential for optimizing warehouse and production environments.

- Incoming goods (WE) and outgoing goods (WA): use of automated systems for fast processing and accurate recording of goods.

- Storage systems: Use of high-bay warehouses and automated storage solutions that maximize space utilization and facilitate inventory management.

- Conveyor systems: Integration of advanced conveyor technologies that ensure a continuous and efficient material flow.

- Picking software and sorting systems: Introduction of advanced picking and sorting systems supported by precise software solutions to minimize errors and speed up order processing.

- Telematics, sensor technology and robotics: Integration of the latest sensor technology and robotics for improved monitoring, automated material handling and preventive maintenance.

- Software for the respective areas: Development and deployment of specialized software solutions that ensure seamless integration and effective management of various processes.

- Complete systems: Providing customized, comprehensive intralogistics systems that cover all aspects from storage to delivery.

Intralogistics of the future

At proLogistik, we believe that the future of intralogistics lies in the further integration of advanced technology, artificial intelligence and sustainable practices. Our commitment to innovation means that we are constantly exploring new ways to increase efficiency, reduce costs and improve warehouse performance.

With our customized solutions, our commitment to customer service and our pioneering role in technological innovation, we are here to help you master your logistics challenges and take your business into the future.

We will be happy to advise you on our products

We are here for you.Give us a call or send us a message. We look forward to welcoming you.

proLogistik Holding GmbH

Fallgatter 1

44369 Dortmund

Tel.: +49 (0) 231 5194-0

Tel.: +41 (0) 44 200 40-00

Tel.: +33 (0) 251 81 85 85

FAQ – Frequently asked questions

Digitalization plays a key role in the evolution of intralogistics. By integrating digital technologies, companies can obtain real-time data about their supply chains, leading to improved decision-making processes, greater efficiency and reduced operating costs. Digitalization also enables the automation of complex processes, improves inventory accuracy, minimizes errors and promotes an agile response to market changes.

AI is a game changer in the world of intralogistics, as it optimizes processes that were previously considered too complex or time-consuming. Through machine learning and data analysis, AI systems can recognize patterns, make predictions and make autonomous decisions that increase efficiency. They improve inventory management, facilitate predictive maintenance, minimize downtime and assist with dynamic route planning, all of which add up to a significant increase in productivity and cost savings.

Intralogistics is crucial for customer satisfaction as it has a direct impact on delivery times, inventory accuracy and order integrity. Optimized warehousing, picking and shipping processes enable companies to ensure fast, reliable and accurate deliveries, increasing customer satisfaction and loyalty. In addition, efficient intralogistics enables a faster response to customer requests and needs, resulting in an improved customer experience and a stronger brand image.