Digitalization is changing the way we live and the way we work – massively. The building materials trade cannot ignore this development. However, processes in this sector in particular are still extremely traditional, especially in the field of intralogistics. However, the pressure to act is growing and is being further intensified by the flourishing e-commerce business. However, initial initiatives to usher in the necessary structural change are already having an impact. This is clearly illustrated by the example of two retail companies that decided to introduce warehouse management software (WMS) and thus set the course for the future.

The convenience of e-commerce has given rise to a new guild of builders. They, as well as DIY enthusiasts, are increasingly researching products and prices on the Internet. But it doesn’t usually stop there, shopping is also increasingly being done online. The change in procurement behavior also poses new challenges for traditional building materials dealers. Although they often use merchandise management systems, their basic functions usually support administrative processes, such as the creation of delivery bills and invoices. The ability to provide information to customers, who like to check availability online in a matter of seconds, is therefore limited. Uncertainty at the inventory level can also lead to successively excessive stocks being built up, which can have a lasting negative impact on the balance sheet.

The consequences of a lack of transparency also become clear, particularly in the course of order picking, for example in the form of missing quantities. These are only recognizable when paper-based order processing has already been initiated. New staff are also often overwhelmed when it comes to finding ordered goods quickly. Unproductive routes and/or empty runs are the result. In this context, companies benefit from the wealth of experience of long-serving employees who are very familiar with the warehouse environment. But sooner or later they will retire from working life.

Focus on optimized processes and services

In view of the associated waste of resources combined with inadequate process efficiency, the building materials trade is called upon to rethink and prepare for the future. However, automation is not the all-important solution, as the range of products on offer is extremely heterogeneous and many of the products are large and bulky. Nevertheless, the processes must be put to the test. In addition to economic aspects, the focus here is on service quality. This is because customers are becoming increasingly demanding. They expect a shopping experience that is subjectively perceived as perfect – not only online, but also at the local retailer. In addition, traceability – also in terms of plagiarism protection – must be taken into account to a much greater extent than was the case years ago.

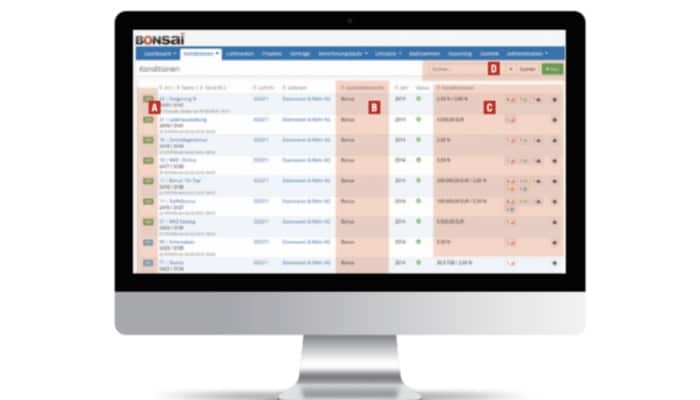

By introducing a warehouse management system (WMS), i.e. moving away from paper-based to digitalized order processing, the building materials trade can set decisive levers in motion in order to be attractive to customers in the long term, differentiate itself from the competition, secure its own market position and, in the best case, expand it further. The latter is also thanks to the option of being able to develop new business models with software support. One such application is the in-house developed pL-Store® Techline, which was developed by proLogistik and tailored to the specific requirements of the building materials, sanitary and technical wholesale sectors, so that only a small amount of additional programming work is required. It is ERP-independent and can therefore be connected to any standard merchandise management system.

For example, functions for seamless batch tracking across the entire process chain are covered as standard. No less relevant for the building materials trade are counter handling and the management of loading aids in circulation (LHM). Incoming and outgoing pallets can be recorded and managed directly in the system using the LHM application. Counter processing, on the other hand, supports the processing of orders that are registered directly in the store. The order is first recorded in the merchandise management system and transmitted in real time to the warehouse management system, which in turn triggers the picking process by informing the employees directly. Prioritization can also be carried out if required. Applications for multi-order picking are also included and it is possible to identify products by entering and recording serial numbers.

The pilot project is followed by the rollout

Hieronimi, a building materials retailer based in Faid/Cochem, also relies on this solution. In January 2018, the company implemented a warehouse management system for the first time in Mülheim, switching from manual to paperless order processing. This also covers a Common Reporting Standard (CRs), which the company combines with the building materials dealer Fassbender-Tenten from Bonn. Both are members of the Bauspar Group, a strategic alliance of building materials dealers that has set itself the task of promoting regional synergies, including in the areas of purchasing, logistics and organization. Against this background, standardized software was also required at the intralogistics level.

The standard solution supports all processes from goods receipt to batch management, online inventory management, chaotic and fixed storage location management, barcode control, paperless picking and freestyle picking for counter handling through to goods issue. Additional, individually relevant applications were added at Hieronimi’s request. For example, it should be possible to record the license plate number for immediate or self-collectors. A monitor was also installed to show customers their current order processing status in the waiting area.

It also had to be ensured that loading aids used in goods issue were reported back to the ERP system for invoicing purposes. Also shown are a paint mixing plant, as mixed paint is not a stock item, and a concrete mixing plant. The challenge with the latter was to initiate a suitable replenishment process for bulk goods. Another advantage of the synchronized interaction of both systems is the improved ability to provide information in direct customer contact. As all goods to be stored are seamlessly recorded and simultaneously transferred to the ERP, their availability can be checked ad hoc by the service employee. This effect, in combination with the subsequent delivery quality, also contributes significantly to customer satisfaction. The transparency of stock levels has increased significantly, while at the same time employees always have an overview of all goods movements. The software-supported permanent inventory is also a particular advantage. There is no need for error-prone, regular surveys using a pen and clipboard. In addition, flexibility in the course of order processing has increased and the picking quality has been noticeably improved.

Complexity mastered with the help of avalanche transceivers

Fassbender-Tenten has also introduced the pL-Store® Techline-LVS as part of a pilot project. In view of the results achieved, the system is now being gradually rolled out to other branches of the Bonn-based building materials retailer. Its product range comprises around 59,000 parts, 8,719 of which are actively stocked. Stocking takes place both in the specialist store itself and in adjacent warehouses. There are also pallet and cantilever racks as well as block and bulk storage areas in the outdoor area. Until the new standard software went live, order picking was conventionally organized manually. The document-based order processing not only caused a great deal of effort, but also proved to be increasingly error-prone and in need of repeated correction in view of the constantly growing product ranges. The proportion of immediate or self-collection customers, for whom comparatively short lead times are of primary relevance, also increased significantly.

Against this background, the decision was made to implement a warehouse management system based on the Common Reporting Standard (CRs). After the first rollouts were completed, it became clear that data quality had been significantly improved. There is inventory transparency and there is no longer any need for manual or double entry, which means that order throughput times have been reduced. As a result, the building materials retailer has recorded an improved level of service for its customers within logistics. Additional integrated company-specific applications, which are not included in the standard version of the WMS, also contribute to this. Among other things, a customer monitor was installed in the waiting area, which shows each individual the processing status of their order. It also had to be ensured that loading aids used in goods issue were reported back to the ERP for invoicing. At the same time, it should be possible to record the respective license plate number for self-collectors.

Special consideration was also given to cash sales as early as the goods issue process. It is important here that the picker is shown the invoice already in the customer’s possession at the beginning so that he knows whether or not loading aids (LHM) have been sold at the same time. At the end of the picking run, the input of the LHM entry is then practically suppressed and the employee only issues what is explicitly listed on the invoice.

The switch from paper-based picking to digitalized processes, including mobile data capture, naturally also placed new demands on operational staff. However, thanks to the experience gained during the first go-live in Rheinbach and the subsequent productive operation, everything went according to plan during the subsequent start-ups. As all goods to be stored are recorded seamlessly and in real time via mobile handheld or terminal and simultaneously transferred to the ERP system, their availability is visible ad hoc. An improved ability to provide information in conjunction with shorter delivery times also helps to further cultivate service quality.

Solid foundation for varying and growing requirements

Alongside the software, proLogistik supplied the required number of handheld devices for mobile data collection and industrial PCs. The IPCs are used on trolleys in incoming goods, for example. Slightly smaller devices are predestined to be carried as on-board computers on a forklift truck. Typical features of these compact “assistants” are a wear-free, capacitive touch surface and a plastic housing that is resistant to aggressive influences and cannot be damaged by (impact) shocks. Special laminated safety glass increases the service life many times over.

Instead of having to handle a pen and clipboard or printed Excel lists, warehouse staff now work with mobile devices. These can be operated in a similar way to a smartphone and guide employees safely through the process without any detours. Last but not least, a modern promotional environment increases the chances of attracting the younger generation to your company. Efficient personnel and resource planning can also be realized on the basis of key figures that are constantly generated and processed by the warehouse management system, thus reducing process costs. In addition, data can be used to develop customer profiles in order to improve individual service. Other decisive advantages of digitized warehouse management are significantly increased information capability and shorter response times. At the same time, the prerequisites are being created for being able to act in real time in a network not only across locations but also across companies and to take advantage of expanded market opportunities.